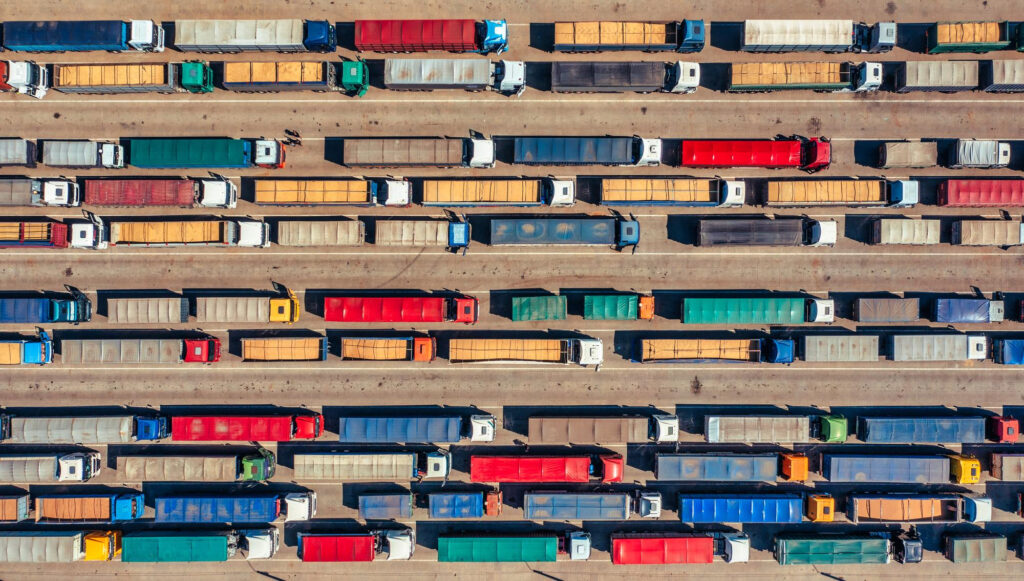

Every link in the supply chain depends on timing, but nowhere is that more apparent than in drayage.

These short-haul truck moves may seem like a small piece of the puzzle, yet when they don’t run smoothly the entire chain feels the impact. A late container pickup can cascade into warehouse bottlenecks, missed distribution windows, and higher transportation costs.

Shippers often focus on long-haul transportation or international ocean freight when thinking about risk, but drayage is where disruptions quietly build.

Port congestion, chassis shortages, driver availability, and equipment breakdowns can all cause delays that ripple through operations. The result is more than an inconvenience. Delays create real financial consequences, from storage and demurrage fees to lost sales opportunities and strained customer relationships.

Understanding how drayage delays disrupt supply chains is the first step in managing them. This article takes a closer look at the common causes, the hidden costs, and the strategies logistics leaders are using to keep freight moving on schedule.

5 Common Causes of Drayage Delays

Drayage is often described as the “last mile of the first mile,” connecting ports and rail yards with warehouses or distribution centers. It is also one of the most unpredictable stages of the journey.

A range of factors can slow down container moves before they ever reach your facility:

1. Port Congestion

When vessels stack up offshore or terminals get backed up, drivers wait in line instead of moving freight. Even a small slowdown at the port gates can translate into hours lost, limiting the number of trips a driver can complete in a day. Congestion has a measurable effect on containership freight rates, according to a 2025 study, and bottlenecks at the port can ripple out into higher costs across the entire logistics chain.

2. Chassis Shortages

Containers don’t move without the right equipment. A shortage of available chassis is one of the most persistent issues in drayage, especially during peak seasons. When drivers can’t secure chassis quickly, freight sits idle, and costs add up.

3. Driver Availability

The drayage sector depends on a reliable pool of drivers who know the local port and rail systems. High turnover, limited capacity, or new regulatory requirements can all thin out that pool.

4. Equipment Breakdowns

From truck maintenance issues to problems with container handling equipment at terminals, mechanical breakdowns are a routine cause of delay. These incidents might only affect one shipment at a time, but when they happen frequently, they add up to real operational setbacks.

5. Customs and Documentation Issues

Missing paperwork or misfiled customs declarations can stop a container in its tracks. Even in a digital environment, drayage relies on accurate documentation at every step. Industry analysis this year noted that new tariff policies drove blank sailings and rerouting, creating unexpected port congestion that cascaded into drayage slowdowns across U.S. gateways.

Each of these issues might seem like an isolated problem, but in practice they overlap. A driver shortage makes congestion worse, chassis shortages make port backlogs longer, and documentation errors magnify the time trucks spend idle.

The Hidden Costs of Drayage Delays

Every hour a container sits still has a price tag attached, and those costs compound quickly. Delays in drayage don’t just disrupt schedules, they eat into margins in ways that are often underestimated.

Demurrage and Detention Fees

Terminals charge demurrage when containers aren’t picked up on time, and carriers assess detention when equipment isn’t returned promptly. Both fees stack up daily, and a single week of delay can add thousands to the bill.

Recent research points out that shrinking free time windows and higher demurrage and detention charges are straining intermodal operations, making the financial impact of drayage delays even harder to absorb.

Storage and Handling Costs

If freight misses its scheduled pickup, companies often scramble to find temporary storage. That means additional handling, extra drayage moves, and higher warehouse expenses — none of which were part of the original budget.

Missed Sales and Production Delays

When components or finished goods arrive late, the effects reach far beyond logistics. Production lines can slow or stop altogether, retail promotions may need to be delayed, and customers lose confidence in on-time delivery promises.

Increased Transportation Spend

A delay at the drayage stage can force businesses to expedite later in the chain just to catch up. That might mean paying premium rates for trucking, air freight, or labor overtime in the warehouse.

Strain on Customer Relationships

These days, delivery performance is a key metric customers watch closely. Consistent delays can lead to strained relationships, reduced repeat business, and long-term reputational damage.

The financial and operational hit from drayage delays is rarely confined to a single shipment.

These costs often show up weeks later in the form of lost revenue or tighter budgets. For many shippers, the real danger lies in how easily small disruptions compound into major setbacks.

How Delays Compound Across the Supply Chain

Picture this: a vessel docks at Port Newark late on a Thursday. Containers are finally offloaded on Friday morning, but congestion at the gate means trucks sit in line for three hours before they even touch a chassis. By the time your container clears, the driver’s allowable hours are nearly up. That load doesn’t reach your warehouse until Monday.

What looks like a two-day delay on paper is actually much bigger in practice:

- Weekend operations thrown off. The warehouse staff you scheduled for Saturday morning has nothing to unload, while Monday’s team suddenly faces a surge of backed-up work.

- Retail commitments missed. The container held seasonal product meant to hit shelves by Sunday. By the time it arrives, the window for promotion has closed.

- Extra costs triggered. You’ve now paid for wasted labor, higher storage fees at the terminal, and a premium trucking move to keep downstream distribution from falling even further behind.

This is how drayage delays stretch far beyond the port gates. They aren’t just about hours lost, but about the ripple of operational inefficiencies throughout the network.

S&P Global’s Q2 2025 analysis tracked congestion across major trade regions and confirmed that U.S. ports remain among the most strained, with delays that directly feed into local drayage bottlenecks.

For supply chain leaders, these compounding effects are often harder to quantify than a line-item fee, but they’re the reason small disruptions feel so outsized.

Strategies to Stay Ahead of Drayage Delays

Shippers who manage drayage well rarely rely on a single tactic. Instead, they layer multiple strategies that give them flexibility when something inevitably goes wrong.

Here’s what actually makes a difference:

1. Build Strong Port Relationships: Every terminal operates differently, and the insiders who move freight fastest are the ones who know the system. Truckers with established relationships at port gates often get real-time updates on equipment shortages or congestion patterns, allowing them to plan smarter. For shippers, aligning with carriers who have those ties can shave hours off container moves.

2. Use Data to Anticipate Trouble: It’s not enough to react once a truck is late. Teams that succeed are watching gate turn times, chassis availability, and vessel schedules daily. Some companies even set up “war rooms” during peak season, tracking live feeds of port conditions. With that visibility, they can reschedule warehouse labor or reassign drivers before the problem escalates. Emerging studies suggest predictive scheduling tools can boost container yard throughput and reduce congestion, offering a glimpse of how technology may ease drayage delays in the years ahead.

3. Diversify Your Options: Relying on a single port or dray provider leaves you exposed. Smart operators keep backup carriers in rotation, maintain access to multiple chassis pools, and consider alternate ports within reach of their network. It costs a little more upfront, but it protects against the far bigger cost of missed deliveries.

4. Prioritize Customs Readiness: One of the quickest ways to lose time is at clearance. Experienced teams prepare documents early, double-check filings, and coordinate with customs brokers to prevent holds. For high-value or high-risk shipments, pre-clearance programs and trusted trader certifications are worth the investment.

5. Tighten Communication Loops: When something does go wrong, speed of communication determines how much damage is done. Operations teams that connect drivers, dispatchers, warehouse managers, and customers in one platform can cut hours off the response time. A real-time notification that a truck is still waiting at the port gives the warehouse a chance to reshuffle schedules instead of sitting idle.

Taken together, these strategies create resilience.

Operations research has shown that smarter planning under uncertainty in drayage procurement can cut costs by more than 20% in modeled scenarios, highlighting the payoff of treating drayage as a strategic function rather than a transactional one.

The reality is no one can eliminate drayage delays entirely. But the companies who treat drayage as a strategic function rather than a commodity are the ones who keep goods flowing, customers happy, and costs in check.

Why Drayage Deserves a Seat at the Strategy Table

For many shippers, drayage has long been treated as a transactional service. Call a carrier, move a box, check it off the list.

But anyone who has dealt with missed pickups, long port queues, or last-minute detention charges knows drayage is anything but a side note. It is the hinge point where international freight meets domestic distribution, and the health of the entire supply chain depends on it.

When delays become the norm, they quietly erode profit margins and weaken customer trust. When drayage is managed as a core part of the strategy, it becomes a competitive advantage.

Companies that invest in visibility tools, nurture carrier relationships, and plan for contingencies are not just reacting to problems. They are creating breathing room in their operations. That agility shows up in lower costs, fewer surprises, and stronger service performance.

The lesson from the inside is simple: do not underestimate the short haul.

Drayage delays may only cover a handful of miles, but their reach extends through every tier of the supply chain. Treating drayage as a priority rather than an afterthought is what separates the companies who stay ahead from those who are always playing catch-up.